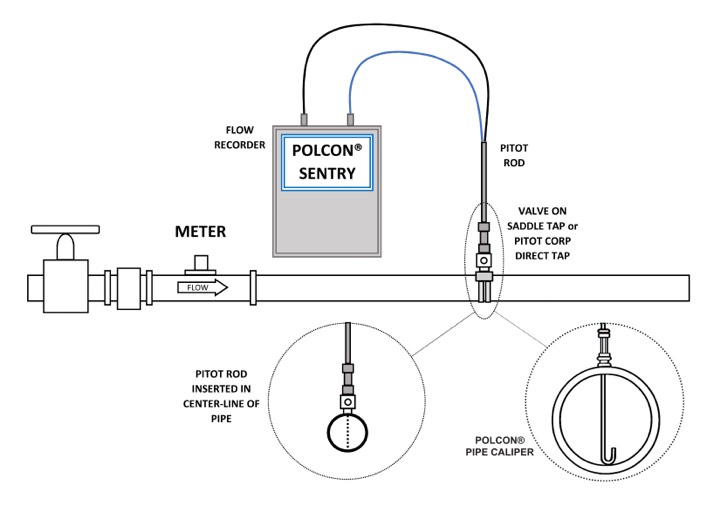

Pitot Testing

M.E. Simpson Co., Inc. employs the use of a Polcon® Pitot Rod to accurately measure velocity of water flowing in a pipe, thereby determining the accuracy of a flow meter at a single flow or over a broad range of flows. This equipment can be used to monitor flows for testing meters up to 108 inches. This procedure consists of placing the Polcon® caliper into the pipe and measuring the inside diameter of the pipe, then placing the Polcon® Pitot Rod into the pipe and measuring the velocity at equidistant points over the cross section. From this, a velocity profile is generated and used to determine the average velocity through the pipe, and the flow-rate through the pipe.

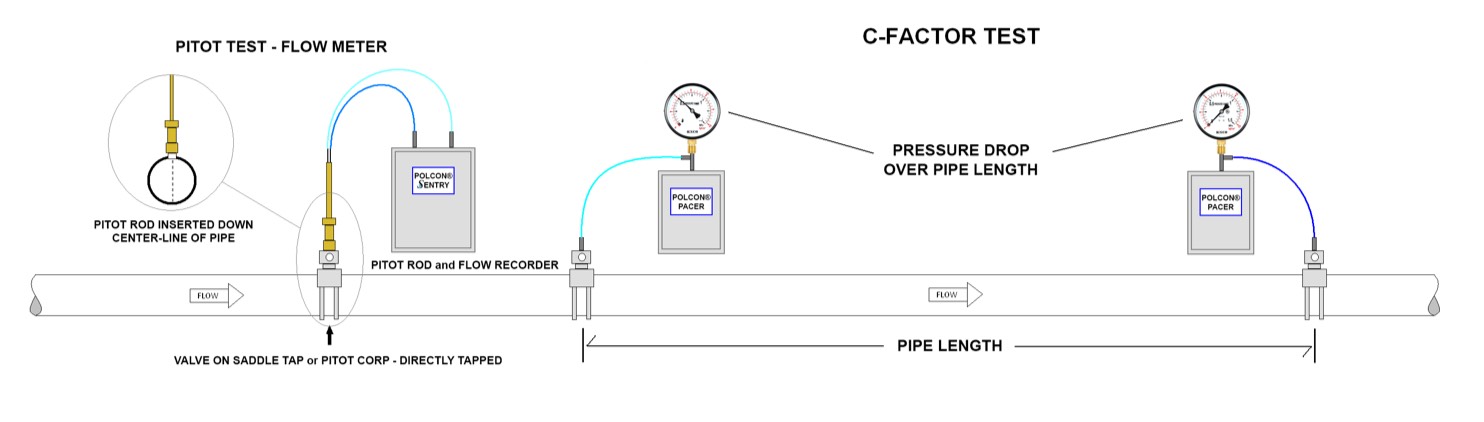

C-Factor Testing

An industry standard for determination of pipeline carrying capacity is the Hazen-Williams friction coefficient “C.” This “C” value is a unitless, dimensionless number that reflects the flow characteristics of the existing pipeline compared to that of a new pipe. The quantity flowing in a pipe with a given head loss varies directly as the value of “C.” Testing is conducted by measuring the pressure differential and water flow over the distance of the pipe under study. This is done with our Polcon® pressure recorders and differential pressure recorders, the Polcon® Sentry and the Polcon® Pacer.

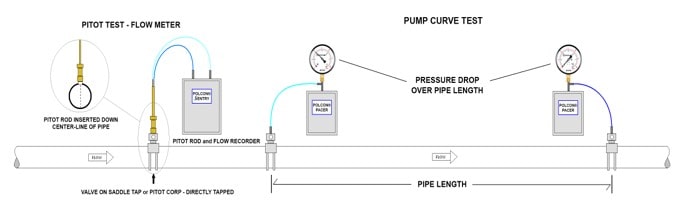

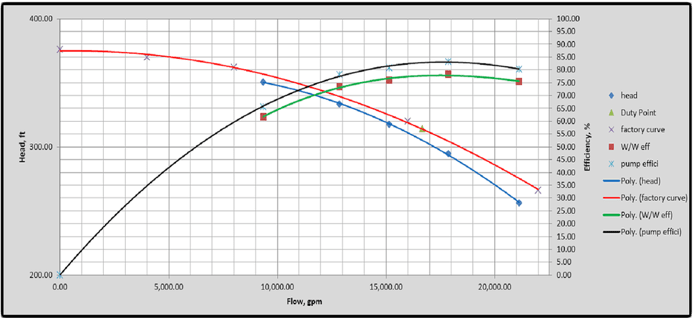

Pump Curve Testing

Selected pumps at a treatment plant or pump station can be tested to determine pump head and pump efficiency. This is accomplished by running the pumps under selected “load” conditions and measuring the input/output pressure, flow velocities, and power supplied to the motor. This information is used to develop pump curves which can be used to determine the optimal operating range of the pump. Additionally, any meter located in series with the pumps can also be checked for accuracy during this process.

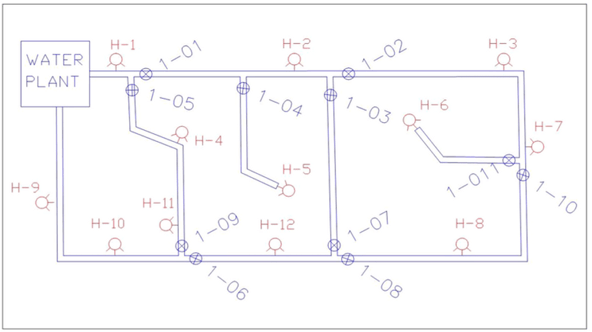

System Flow Measuring and Testing

The water distribution system flow measuring and testing program is designed to monitor the continuous flow in specifically selected areas of the water distribution system. Technicians will flow-monitor your water distribution system in the designated areas for trend analysis, which can lead to the discoveries of leaks, meter inaccuracies, and other water distribution system problems. Often, this data is used to calibrate hydraulic models.

Explore our Polcon® Products

See how our Polcon® products and services work together to serve your water system needs.

View Polcon® Products